Induction & Heat Transfer: The Revolutionary Guide!

Electromagnetic fields, fundamental to the operation of induction heating systems, directly influence the efficiency of induction helps in heat transfe. Comsol Multiphysics, a leading simulation software, allows engineers to model and analyze the intricate thermal behaviors produced by induction, optimizing performance. The work of Michael Faraday significantly advanced the understanding of electromagnetic induction, laying the groundwork for modern applications in areas like manufacturing facilities that rely on precise heating processes.

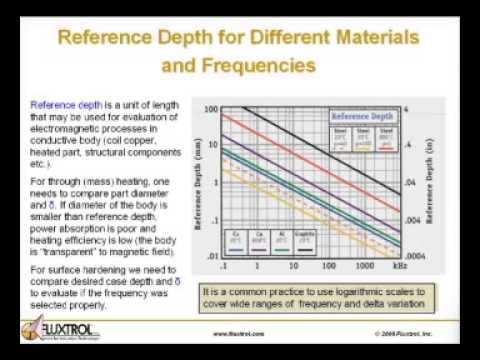

Image taken from the YouTube channel Fluxtrol , from the video titled Power Transfer Factor In Induction Heating .

Induction heating, a technology rapidly gaining traction across diverse industries, represents a paradigm shift in how we approach heat transfer. Its growing significance stems from its unique ability to deliver heat precisely, efficiently, and in a highly controllable manner. From the mundane, like cooking, to complex industrial processes, induction heating is transforming operations.

The Rise of Induction Technology

Traditional heating methods often suffer from inefficiencies, relying on indirect heat sources and leading to substantial energy losses. In contrast, induction heating generates heat directly within the target material itself, minimizing waste and maximizing energy utilization. This inherent efficiency is a key driver of its increasing adoption.

Induction: The Cornerstone of Efficient Heat Transfer

At its core, this article highlights how induction is instrumental in achieving highly efficient heat transfer. Unlike conventional methods that heat from the outside in, induction heating leverages electromagnetic fields to induce heat directly within the material.

This results in faster heating cycles, reduced energy consumption, and improved process control. The ability to precisely target the heat application also minimizes thermal stress and distortion, contributing to enhanced product quality.

A Roadmap Through the World of Induction

This exploration will begin with the fundamental principles governing induction heating, delving into the science of electromagnetic induction and its relationship to heat generation. We will then examine the critical role of material properties and how they influence the effectiveness of the induction process.

Next, we will showcase a diverse range of applications. From the kitchen to the factory floor, demonstrating the technology’s versatility. Finally, we will dissect the key advantages of induction heating, including its superior efficiency, unparalleled precision, and enhanced control capabilities. This will illuminate why induction is becoming the preferred choice in an ever-increasing number of applications.

Traditional heating relies on external sources, but induction cleverly generates heat within the material itself. Understanding how this occurs requires delving into the core scientific principles at play. Let's explore the fascinating science of electromagnetic induction and its role in efficiently creating heat.

The Science Behind the Heat: Electromagnetic Induction Explained

At the heart of induction heating lies the phenomenon of electromagnetic induction, a fundamental principle governing the interplay between electricity and magnetism. It's how electrical energy is converted into thermal energy, with remarkable speed and precision.

Core Principles of Electromagnetic Induction

Electromagnetic induction describes how a changing magnetic field can induce an electromotive force (EMF), essentially a voltage, in a conductor. This principle is critical to understanding how induction heating works.

A magnetic field in motion, or one that varies in strength, creates an electric field. If a conductive material is placed within this changing magnetic field, the electric field drives the flow of electrons, generating an electrical current within the material.

Faraday's Law: The Foundation

The quantitative relationship governing electromagnetic induction is described by Faraday's Law of Induction. In simplified terms, Faraday's Law states that the magnitude of the induced EMF is proportional to the rate of change of the magnetic flux through a circuit.

This law explains why a rapidly changing magnetic field produces a greater EMF and, consequently, a stronger induced current, leading to more efficient heating. The faster the change in the magnetic field, the more powerful the heating effect.

The Role of Eddy Currents in Induction Heating

The currents generated within the material due to electromagnetic induction are known as eddy currents. These circulating currents are the key to heating the material from within.

Eddy currents flow in closed loops within the conductor, perpendicular to the magnetic field. Their magnitude and distribution depend on the strength and frequency of the magnetic field, as well as the material's electrical conductivity and permeability.

Eddy Current Density and Heat Transfer

The density of eddy currents directly dictates the rate of heat generation. A higher eddy current density means more electrons are in motion, encountering resistance, and thus producing more heat.

This relationship allows for precise control over the heating process by adjusting the frequency and strength of the applied magnetic field. By focusing the eddy currents in specific areas, induction heating can achieve highly localized heating effects.

Heat Transfer Mechanisms in Induction Heating

Once heat is generated by eddy currents, it's distributed throughout the material via several heat transfer mechanisms. These include conduction, radiation, and, to a lesser extent, convection.

Conduction: Propagation Through Thermal Conductivity

Conduction is the primary mode of heat transfer within the material. It relies on the transfer of energy from more energetic particles to less energetic ones through molecular collisions.

The efficiency of heat conduction depends on the material's thermal conductivity. Materials with high thermal conductivity, such as copper and aluminum, distribute heat more rapidly and evenly.

Radiation: Heat Transfer at Elevated Temperatures

At higher temperatures, radiation becomes a significant factor in heat transfer. All objects emit electromagnetic radiation, and the amount and spectrum of radiation depend on the object's temperature.

In induction heating, radiation can contribute to heat loss from the surface of the material, but it also plays a role in distributing heat to surrounding objects.

Minimizing Convective Losses for Optimal Efficiency

Convection, the transfer of heat through the movement of fluids (liquids or gases), can also play a role. In many induction heating applications, minimizing convective losses is essential for maximizing efficiency.

This can be achieved through insulation or by controlling the surrounding environment to reduce air currents. Reducing convective losses helps ensure that the heat generated remains within the material being heated.

Eddy currents, skillfully directed by electromagnetic induction, now course through the material. But what exactly transforms this electrical activity into the tangible warmth we associate with induction heating? The answer lies in the fundamental relationship between electricity, resistance, and heat, a relationship elegantly described by Joule's First Law.

Joule Heating and Material Properties: Key Factors in Induction

The effectiveness of induction heating is not solely dependent on the principles of electromagnetism. It is also intimately linked to Joule's First Law and the inherent properties of the materials being heated. Understanding these factors is crucial for optimizing the process and selecting the appropriate materials for induction applications.

The Role of Joule's Law

Joule's First Law, expressed as Q = I2Rt, where Q represents heat generated, I is the current, R is the resistance, and t is time, is the cornerstone of understanding how induction heating works at a microscopic level.

This law states that the heat generated in a conductor is directly proportional to the square of the current, the resistance of the conductor, and the time for which the current flows.

In the context of induction heating, the eddy currents induced within the material act as the 'I' in Joule's Law.

Current and Resistance: The Dynamic Duo

The amount of heat generated is acutely sensitive to both current (I) and resistance (R). A higher current flow, even with moderate resistance, leads to a significant increase in heat generation due to the squared relationship.

Similarly, a material with higher electrical resistance will generate more heat for the same amount of current flowing through it. This interplay between current and resistance is carefully manipulated in induction heating to achieve desired temperature profiles and heating rates.

Joule Heating: The Primary Heat Transfer Mechanism

Joule heating is not merely a byproduct of electrical current; it is the primary mechanism through which electrical energy transforms into thermal energy within the induction heating process. The induced eddy currents, encountering the material's inherent resistance, dissipate energy in the form of heat.

This heat then spreads through the material via conduction, contributing to the overall temperature increase. The design of the induction coil and the frequency of the alternating current are carefully controlled to maximize eddy current density and, consequently, Joule heating within the target area.

Material Properties: Metals Take Center Stage

Not all materials are created equal when it comes to induction heating. Metals, with their high electrical conductivity and magnetic permeability, are particularly well-suited for this heating method.

The ability of metals to readily conduct eddy currents and their responsiveness to magnetic fields makes them ideal candidates for efficient and rapid heating.

The specific type of metal also plays a role. Ferrous metals, such as steel and iron, exhibit ferromagnetic properties, enhancing their interaction with the magnetic field and further improving heating efficiency.

Non-ferrous metals, like aluminum and copper, can also be effectively heated using induction, although often requiring higher frequencies or specialized coil designs due to their lower magnetic permeability. Ultimately, material selection is a key consideration in optimizing induction heating for specific applications.

Eddy currents, skillfully directed by electromagnetic induction, now course through the material. But what exactly transforms this electrical activity into the tangible warmth we associate with induction heating? The answer lies in the fundamental relationship between electricity, resistance, and heat, a relationship elegantly described by Joule's First Law.

Having examined the scientific underpinnings of induction heating, from electromagnetic induction and eddy currents to the crucial role of Joule's Law, it becomes compelling to explore the practical manifestations of this technology. Its versatility is truly remarkable, spanning from the familiar domestic environment to the high-tech factory floor. Let's delve into the diverse applications that highlight the transformative power of induction heating across a wide spectrum of industries.

Applications Across Industries: From Kitchen to Factory Floor

Induction heating, with its inherent efficiency and precision, has permeated numerous industries, revolutionizing processes and enhancing productivity. From the subtle art of culinary creation to the robust demands of industrial manufacturing, induction technology proves its adaptability and value. This section explores a selection of these applications, showcasing the breadth and depth of its impact.

Induction Cooking: A Revolution in the Kitchen

The modern kitchen has embraced induction cooktops as a safer, faster, and more energy-efficient alternative to traditional electric or gas stoves.

Efficiency is a key factor. Induction cooktops directly heat the cookware, minimizing heat loss and delivering significantly faster cooking times.

The precise temperature control offered by induction allows for delicate simmering and rapid boiling with ease.

Safety is another notable advantage, as the cooktop surface itself remains relatively cool, reducing the risk of burns. Only the cookware heats up, minimizing wasted energy.

The ease of cleaning and sleek aesthetic further contribute to the appeal of induction cooktops in contemporary kitchens.

Industrial Heating: Forging, Heat Treatment, and More

The robust capabilities of induction heating find extensive application in various industrial processes.

Forging: Precision and Speed

Induction heating offers rapid and localized heating for forging applications, allowing for precise control over the temperature and duration of the heating cycle.

This results in improved material properties, reduced energy consumption, and enhanced productivity compared to traditional furnace heating.

Heat Treatment: Tailoring Material Properties

Induction heating enables precise heat treatment of metal components, allowing manufacturers to tailor the hardness, strength, and durability of materials to specific requirements.

Processes like surface hardening, annealing, and tempering can be efficiently and accurately performed using induction technology.

The localized nature of induction heating minimizes distortion and scale formation, resulting in improved part quality and reduced post-processing requirements.

Other Industrial Applications

Beyond forging and heat treatment, induction heating is also employed in:

- Shrink fitting

- Brazing

- Melting of metals

Its ability to deliver rapid, controlled heat makes it an ideal choice for a wide range of industrial applications.

Welding: Precision and Efficiency in Joining

Induction welding offers a precise and efficient method for joining metal components, particularly in high-volume production environments.

It provides several advantages over traditional welding techniques, including:

- Faster welding speeds

- Reduced heat-affected zone

- Minimal distortion

- Improved weld quality

Induction welding is widely used in the manufacturing of:

- Pipes and tubes

- Automotive components

- Structural steel elements

The localized heating and precise control offered by induction technology result in stronger, more reliable welds with minimal material waste.

Having seen induction heating at work in a variety of settings, it's natural to ask: what are the concrete advantages that make it so appealing compared to more conventional heating methods? The answer lies in a trifecta of benefits: efficiency, precision, and control, each of which contributes to making induction heating a compelling choice for many modern applications.

Advantages of Induction Heating: Efficiency, Precision, and Control

Induction heating distinguishes itself from traditional methods through a constellation of benefits, primarily efficiency, precision, and control. These advantages not only improve operational performance but also contribute to greater safety and reduced environmental impact.

Unmatched Efficiency: Converting Energy into Heat with Minimal Waste

One of the most compelling arguments for induction heating is its superior energy efficiency. Traditional heating methods, such as gas furnaces or resistance heaters, often lose a significant portion of their energy to the surrounding environment. This loss occurs through radiation, convection, and conduction, resulting in wasted energy and increased operating costs.

In contrast, induction heating directly heats the target material itself. By minimizing heat loss, induction heating achieves significantly higher energy conversion rates. This leads to reduced energy consumption, lower utility bills, and a smaller carbon footprint.

The efficiency of induction heating can often exceed 80%, far surpassing many conventional heating methods. This makes it an attractive option for industries seeking to reduce energy costs and improve sustainability.

Precision Heating: Targeted Heat Where It's Needed Most

Beyond efficiency, induction heating offers unparalleled precision in heat application. Unlike traditional methods that heat the entire workpiece or a large area, induction focuses the heat on a specific, localized region. This targeted approach minimizes distortion and oxidation, resulting in higher-quality products and reduced material waste.

This level of precision is crucial in applications such as heat treating, where only certain areas of a component require hardening. Induction heating allows for precise control over the heated zone, ensuring that only the targeted area reaches the desired temperature. This results in improved mechanical properties and extended product lifespan.

The ability to precisely control the heating zone is a key advantage of induction heating, enabling manufacturers to achieve consistent and repeatable results.

Enhanced Control: Tailoring Heat for Specific Applications

The high degree of control afforded by induction heating is another key differentiator. Through precise adjustment of parameters like frequency, power, and heating time, the heating process can be finely tuned to meet the specific requirements of each application.

This level of control is especially beneficial in processes such as annealing and tempering, where precise temperature control is essential for achieving desired material properties. Induction heating allows for the creation of custom heating profiles, ensuring that the material is heated evenly and consistently.

The exceptional control capabilities of induction heating lead to improved product quality, reduced scrap rates, and optimized production processes. Furthermore, modern induction systems often incorporate sophisticated monitoring and feedback mechanisms, further enhancing process control and ensuring consistent results.

Safety and Environmental Benefits

In addition to efficiency, precision, and control, induction heating offers significant safety and environmental advantages. Because it does not involve open flames or hot surfaces, it reduces the risk of burns and fires.

Moreover, induction heating is a clean and environmentally friendly technology. It does not produce combustion byproducts, such as greenhouse gases or particulate matter, making it a sustainable alternative to traditional heating methods. By reducing energy consumption and minimizing pollution, induction heating contributes to a cleaner and healthier environment.

The inherent safety features and environmental benefits of induction heating make it a responsible choice for companies seeking to minimize their environmental impact and improve workplace safety.

Video: Induction & Heat Transfer: The Revolutionary Guide!

Frequently Asked Questions: Induction & Heat Transfer

This FAQ section addresses common questions about induction heating and its role in heat transfer, further clarifying the concepts presented in our revolutionary guide.

What is Induction Heating and how is it different from conventional heating?

Induction heating is a non-contact heating method that uses electromagnetic induction to generate heat within a conductive material. Unlike conventional heating, which relies on external heat sources, induction helps in heat transfer by creating heat directly inside the object.

How does induction help in heat transfer compared to other methods?

Induction heating allows for very precise and localized heating. Because the heat is generated internally, there's less energy waste in heating surrounding air or equipment. This directness is how induction helps in heat transfer so effectively compared to methods like convection or radiation.

What are the main applications of induction heating?

Induction heating is widely used in various industries, including heat treating of metals, forging, brazing, melting, and cooking. Its efficiency and precision make it ideal for processes requiring controlled and rapid heating.

What factors affect the efficiency of induction heating?

Several factors influence induction heating efficiency, including the material's properties (conductivity, permeability), the frequency of the alternating current, the coil design, and the distance between the coil and the workpiece. Efficient coil design and proper frequency selection ensures induction helps in heat transfer with optimal results.