Copper Specific Heat: The Ultimate FAQ Guide You Need!

Understanding heat transfer is crucial in numerous engineering applications, and copper, a common metallic element, plays a vital role. Thermodynamics principles govern the behavior of materials like copper when subjected to heat, directly influencing its specific heat capacity. The National Institute of Standards and Technology (NIST) provides valuable data and resources that researchers and engineers utilize to accurately determine and apply thermal properties. In essence, copper specific heat is a fundamental property influencing its suitability in thermal applications like heat sinks and exchangers.

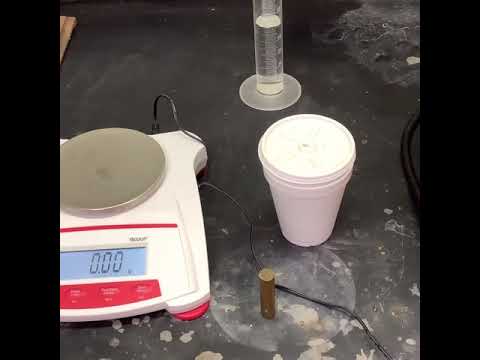

Image taken from the YouTube channel Andrew Colomac , from the video titled Determining the specific heat of copper .

Copper, a reddish-gold metal, is ubiquitous in modern society.

Its applications span across diverse industries, from electrical wiring and plumbing to coinage and even culinary tools.

Its malleability, ductility, and exceptional electrical and thermal conductivity make it an indispensable material in countless applications.

Copper's Widespread Applications

Consider the intricate circuitry within electronic devices, the reliable piping systems delivering clean water, or the efficient heat exchangers found in power plants.

In all these applications, copper plays a pivotal role due to its unique combination of properties.

The demand for copper continues to grow as technology advances and infrastructure expands, highlighting its enduring significance in the global economy.

Understanding Specific Heat Capacity

But what governs copper's behavior when exposed to heat? The answer lies in its specific heat capacity.

Specific heat capacity is a fundamental property of matter that dictates how much energy is required to raise the temperature of a substance by a certain amount.

A material with a high specific heat capacity requires more energy to change its temperature compared to a material with a low specific heat capacity.

This property profoundly impacts how a material responds to thermal energy and how effectively it can store or transfer heat.

The Importance of Copper's Specific Heat

Copper's specific heat capacity is crucial to understanding its thermal behavior.

It dictates how quickly copper heats up or cools down and its ability to absorb and dissipate heat.

This is particularly important in applications like heat sinks, where copper is used to draw heat away from sensitive electronic components, preventing overheating and ensuring reliable operation.

Furthermore, understanding copper's specific heat is essential in various industrial processes involving heat transfer, allowing engineers to design efficient and effective systems.

Copper's Specific Heat: Answering Your Questions

This article serves as a comprehensive guide to answering frequently asked questions about copper's specific heat.

We will explore the definition of specific heat capacity, delve into the specific heat value of copper, and discuss the factors that can influence this property.

Additionally, we will examine how copper's specific heat is measured, its impact on heat transfer, and its relationship to the fundamental laws of thermodynamics.

By the end of this guide, you will have a thorough understanding of copper's specific heat and its significance in various real-world applications.

Demystifying Specific Heat Capacity: A Concise Definition

We've established the importance of specific heat in understanding copper's thermal properties, but what exactly is specific heat capacity? Let's delve into a clear and concise definition of this fundamental concept.

Defining Specific Heat Capacity

In its simplest form, specific heat capacity is the amount of heat energy required to raise the temperature of one gram of a substance by one degree Celsius (or one Kelvin). It’s an intrinsic property, meaning it's inherent to the material itself. Think of it as a measure of a substance's resistance to temperature change.

A substance with a high specific heat capacity requires a significant amount of energy to alter its temperature, while a substance with a low specific heat capacity will experience a more dramatic temperature change with the same energy input.

This property is what allows some materials to act as excellent heat reservoirs or insulators.

Specific Heat Capacity vs. Heat Capacity: Understanding the Difference

It's crucial to distinguish between specific heat capacity and the more general term, heat capacity. Heat capacity refers to the amount of heat required to raise the temperature of an entire object by one degree Celsius (or one Kelvin).

The key difference lies in the dependence on mass. Specific heat capacity is an intensive property, independent of the amount of substance, whereas heat capacity is an extensive property, directly proportional to the mass of the object.

Therefore, a large copper block will have a higher heat capacity than a small copper block, but both will possess the same specific heat capacity.

The Relationship to Thermal Energy and Temperature Changes

Specific heat capacity directly links thermal energy transfer to temperature changes within a substance. The relationship is expressed mathematically as:

Q = mcΔT

Where:

- Q represents the heat energy transferred (in Joules).

- m is the mass of the substance (in grams or kilograms).

- c is the specific heat capacity (in J/g°C or J/kg⋅K).

- ΔT is the change in temperature (in °C or K).

This equation reveals that the amount of heat (Q) needed to cause a specific temperature change (ΔT) is directly proportional to both the mass (m) of the substance and its specific heat capacity (c).

In essence, a higher specific heat capacity implies that more energy is needed to achieve the same temperature change for a given mass. Understanding this relationship is fundamental to predicting and controlling thermal behavior in various applications.

Having clarified the definition of specific heat capacity and distinguished it from heat capacity, we can now focus on the specifics of copper itself. What is the actual value of its specific heat, and what factors can cause this value to fluctuate?

The Specific Heat of Copper: Values, Units, and Influencing Factors

The specific heat capacity of copper is a precisely measured value, crucial for calculations in thermodynamics, engineering, and materials science. Knowing this value enables accurate predictions of copper's thermal behavior in a wide range of applications.

Standard Specific Heat Value of Copper

At a temperature of 25°C (298 K), the specific heat capacity of pure copper is approximately:

- 0.385 J/g°C (Joules per gram per degree Celsius)

- 385 J/kg⋅K (Joules per kilogram per Kelvin)

These values are widely accepted and can be found in reputable sources such as:

- Engineering Toolbox

- CRC Handbook of Chemistry and Physics

- NIST Chemistry WebBook

It's important to always cite your sources to ensure accuracy and credibility in scientific and engineering contexts.

Understanding the Units

The units of specific heat capacity are crucial for proper calculations and understanding.

J/g°C (Joules per gram per degree Celsius)

This unit indicates the amount of energy (in Joules) required to raise the temperature of one gram of a substance by one degree Celsius. It is a commonly used unit in chemistry and materials science due to its convenient scale for laboratory experiments and material characterization.

J/kg⋅K (Joules per kilogram per Kelvin)

This unit expresses the same physical quantity but uses kilograms and Kelvin. One Kelvin is the same size as one degree Celsius, so the numerical value only changes due to the change in mass units (grams to kilograms). It is frequently used in large-scale engineering applications and theoretical calculations within physics.

Essentially, both units represent the same property, just expressed in different scales.

Factors Influencing Copper's Specific Heat

While the value of 0.385 J/g°C is widely used for pure copper at room temperature, several factors can influence its specific heat capacity:

Temperature

The specific heat capacity of any substance, including copper, is temperature-dependent.

As temperature increases, the specific heat capacity generally increases slightly. This occurs because at higher temperatures, more energy is needed to excite the various vibrational modes within the copper lattice.

Therefore, while 0.385 J/g°C is a good approximation at 25°C, the specific heat will be different at, say, 100°C or -50°C. For high-precision applications, temperature-dependent specific heat values should be used.

Impurities and Alloying

The presence of impurities or alloying elements can also affect copper's specific heat. Even small amounts of other elements can alter the vibrational characteristics of the copper lattice, changing how it absorbs and stores thermal energy.

For example, adding zinc to copper to create brass will change the specific heat capacity. The exact value will depend on the composition of the alloy.

Phase Changes

While copper remains solid under most operating conditions, its specific heat will drastically change during phase transitions (e.g., melting). The latent heat of fusion must be considered separately from specific heat when calculating energy requirements for phase changes.

Having established the specific heat value of copper and considered the factors that can cause it to change, the question naturally arises: how do we actually measure this property?

Measuring Copper's Specific Heat: Calorimetry Explained

Calorimetry is the experimental technique used to measure the amount of heat exchanged during a chemical or physical process. At its core, it's about carefully tracking energy transfer. This method is the cornerstone for determining the specific heat of various substances, including copper.

Calorimetry: Quantifying Heat Transfer

Calorimetry relies on the principle of energy conservation. In a closed system, heat lost by one substance is gained by another. A calorimeter is the device used to measure this heat transfer. It is designed to thermally isolate its contents, minimizing heat exchange with the surroundings.

The basic equation governing calorimetry is:

Q = mcΔT

Where:

- Q = Heat transferred (in Joules)

- m = Mass of the substance (in grams or kilograms)

- c = Specific heat capacity (in J/g°C or J/kg⋅K)

- ΔT = Change in temperature (in °C or K)

By carefully measuring Q, m, and ΔT, we can solve for 'c', the specific heat capacity.

Determining Copper's Specific Heat: A Step-by-Step Approach

The process of measuring copper's specific heat using a calorimeter typically involves these steps:

-

Prepare the Calorimeter: A known mass of water (mwater) is placed inside the calorimeter. The initial temperature of the water (Tinitial, water) is carefully recorded.

-

Heat the Copper Sample: A known mass of copper (mcopper) is heated to a higher temperature (Tinitial, copper). This can be done using a hot plate or an oven. The temperature must be precisely measured.

-

Introduce the Copper to the Calorimeter: The heated copper sample is quickly transferred into the calorimeter containing the water. The calorimeter is then sealed to minimize heat loss.

-

Monitor Temperature Change: The water is stirred gently to ensure uniform temperature distribution. The temperature of the water is monitored until it reaches a stable maximum value (Tfinal).

-

Calculate the Specific Heat: Using the principle of heat exchange (Qlost by copper = Qgained by water), the specific heat of copper (ccopper) can be calculated using the following equation:

mcopper ccopper (Tinitial, copper - Tfinal) = mwater cwater (Tfinal - Tinitial, water)

Where cwater is the specific heat capacity of water (approximately 4.186 J/g°C).

By rearranging the equation and plugging in the measured values, the specific heat of copper can be determined.

Sources of Error and Mitigation Strategies

While calorimetry is a powerful technique, several factors can introduce errors into the measurements. It's crucial to understand these potential pitfalls and implement strategies to minimize their impact.

Heat Loss to the Surroundings

No calorimeter is perfectly insulated. Some heat will inevitably be exchanged with the environment. This can lead to an underestimation of the heat absorbed by the water and, consequently, an inaccurate specific heat value for copper.

- Minimization: Using a well-insulated calorimeter and conducting the experiment quickly can reduce heat loss. Applying a cooling correction based on the rate of temperature change can also improve accuracy.

Incomplete Heat Transfer

If the copper sample and the water do not reach thermal equilibrium, the final temperature reading will be inaccurate.

- Minimization: Stirring the water thoroughly and allowing sufficient time for the system to reach equilibrium are essential.

Inaccurate Temperature Measurements

Errors in temperature readings directly impact the accuracy of the calculated specific heat.

- Minimization: Using a calibrated thermometer with high precision is crucial. Ensuring good thermal contact between the thermometer and the water is also important.

Heat Absorption by the Calorimeter

The calorimeter itself absorbs some heat during the process. This needs to be accounted for.

- Minimization: Determining the heat capacity of the calorimeter (the amount of heat required to raise its temperature by 1°C) allows for a correction to be applied in the calculations. This can be done by performing a separate calibration experiment.

By carefully controlling these factors and applying appropriate corrections, accurate measurements of copper's specific heat can be obtained through calorimetry.

Having established the specific heat value of copper and considered the factors that can cause it to change, the question naturally arises: how does this property actually play out in real-world scenarios where heat needs to be managed?

Copper's Specific Heat and its Role in Heat Transfer

Copper's effectiveness in heat transfer is a cornerstone of countless applications, from the mundane to the highly sophisticated. Its specific heat capacity, while not the highest among all materials, plays a crucial role in how and why copper excels at conducting heat. Let's delve into this relationship.

How Specific Heat Influences Heat Conduction

While thermal conductivity primarily dictates how quickly heat moves through a material, specific heat capacity affects the temperature change a material undergoes when it absorbs or releases heat.

Materials with high specific heat require more energy to achieve a given temperature change. Copper, with its relatively high specific heat, can absorb a considerable amount of heat energy with a comparatively small temperature increase.

This characteristic is particularly important when dealing with applications where temperature stability is crucial, or where heat needs to be absorbed and dissipated efficiently without causing drastic temperature fluctuations.

Copper's Specific Heat Compared to Other Materials

To truly appreciate copper's role, it's important to consider where it stands relative to other common materials. Water, for example, has a significantly higher specific heat. However, water's limitations (phase changes, corrosion) often make it unsuitable for many applications where copper shines.

Aluminum, another common heat transfer material, has a lower specific heat than copper. This means that for the same amount of heat absorbed, aluminum will experience a larger temperature increase than copper.

While aluminum is lighter and often cheaper, copper's ability to maintain a more stable temperature profile under thermal load gives it a distinct advantage in applications where temperature regulation is paramount.

Real-World Applications: Leveraging Copper's Thermal Properties

Copper's specific heat, in conjunction with its high thermal conductivity, makes it ideal for a wide range of applications:

Heat Sinks

In electronics, components like CPUs and GPUs generate significant amounts of heat. Heat sinks, often made of copper, are used to draw heat away from these components, preventing overheating and ensuring stable performance.

Copper's ability to absorb a substantial amount of heat before experiencing a significant temperature rise allows the heat sink to function effectively in maintaining lower temperatures.

Cookware

Copper-bottomed cookware is prized for its even heat distribution. The copper layer quickly spreads heat across the bottom of the pan, preventing hot spots and ensuring consistent cooking.

The copper's specific heat helps to moderate temperature changes, preventing scorching and allowing for more precise temperature control.

Heat Exchangers

In industrial processes and HVAC systems, heat exchangers are used to transfer heat between fluids. Copper tubes are often used in these exchangers due to their excellent heat transfer properties.

The specific heat of copper, in conjunction with its high conductivity, ensures efficient heat transfer, maximizing the performance of the heat exchanger.

In conclusion, copper's specific heat capacity, working in tandem with its exceptional thermal conductivity, is fundamental to its widespread use in heat transfer applications. Its ability to absorb significant heat while maintaining temperature stability makes it an invaluable material in diverse industries.

Having established the specific heat value of copper and considered the factors that can cause it to change, the question naturally arises: how does this property actually play out in real-world scenarios where heat needs to be managed?

Connecting Copper's Specific Heat to the First Law of Thermodynamics

The First Law of Thermodynamics, a cornerstone of physics, provides a fundamental framework for understanding energy transformations. It dictates that energy cannot be created nor destroyed, only converted from one form to another. How does this seemingly abstract principle connect to the tangible property of copper's specific heat? The answer lies in understanding how specific heat governs the energy required to alter a substance's temperature.

The First Law: A Foundation of Energy Conservation

At its core, the First Law of Thermodynamics is a statement about the conservation of energy within a closed system. The change in internal energy (ΔU) of a system equals the net heat added to the system (Q) minus the net work done by the system (W): ΔU = Q - W.

In scenarios involving copper and its specific heat, we often focus on situations where minimal or no work is done (W ≈ 0). Therefore, the equation simplifies to ΔU = Q, indicating that the change in internal energy is primarily determined by the heat transferred.

Specific Heat as an Embodiment of the First Law

Copper's specific heat capacity directly quantifies the relationship described by the First Law. It tells us precisely how much heat energy (Q) is required to raise the temperature of a given mass of copper by one degree Celsius (or one Kelvin).

Mathematically, this relationship is expressed as:

Q = mcΔT

Where:

- Q = Heat energy transferred (in Joules)

- m = Mass of the copper (in grams or kilograms)

- c = Specific heat capacity of copper (in J/g°C or J/kg⋅K)

- ΔT = Change in temperature (in °C or K)

This equation is a direct consequence of the First Law, demonstrating how energy input (Q) directly translates into a change in the material's internal energy, reflected by its temperature change (ΔT). The specific heat (c) acts as the proportionality constant between these two variables.

Illustrative Examples

Consider two practical examples to solidify this concept:

Heating Copper Wire

Imagine heating a copper wire by passing an electrical current through it. As electrical energy is converted into heat (Q), the wire's temperature increases (ΔT). The amount of temperature increase is directly proportional to the specific heat capacity of copper. A lower specific heat would mean a greater temperature increase for the same amount of heat energy applied.

Cooling a Copper Block

Conversely, imagine placing a hot copper block into a cold water bath. Heat will transfer from the copper block to the water. The amount of heat the copper loses (Q) will result in a decrease in its temperature (ΔT). Again, the specific heat determines how much the temperature drops for a given amount of heat lost.

Implications and Considerations

The connection between copper's specific heat and the First Law has profound implications:

- Predictability: It allows us to accurately predict the temperature response of copper to heat inputs or outputs.

- Engineering Design: It is essential for designing systems where temperature control is critical, such as heat exchangers, electronic cooling systems, and various industrial processes.

- Energy Efficiency: Understanding this relationship enables optimizing processes to minimize energy waste and maximize efficiency.

In conclusion, copper's specific heat is not just an isolated material property. It is a direct manifestation of the fundamental First Law of Thermodynamics, governing the relationship between heat, temperature, and energy conservation. Its accurate measurement and application are vital for a wide range of engineering and scientific endeavors.

Practical Applications: Leveraging Copper's Specific Heat in the Real World

The theoretical understanding of copper's specific heat is valuable, but its true worth shines when applied to solving real-world engineering challenges. Copper's ability to absorb and dissipate heat efficiently makes it indispensable in a wide array of applications. Its thermal properties are not merely academic; they are the bedrock of countless technologies and industrial processes that shape our daily lives.

Cooling Systems and Heat Exchangers: A Thermal Symphony

One of the most prominent applications of copper's specific heat lies in cooling systems and heat exchangers. These systems are designed to transfer heat from one medium to another, and copper's high thermal conductivity and respectable specific heat make it an ideal material for the job.

In HVAC (Heating, Ventilation, and Air Conditioning) systems, copper coils are used extensively to absorb or release heat as air passes over them. This allows for efficient temperature regulation in buildings. Similarly, in refrigeration systems, copper tubing facilitates the transfer of heat away from the refrigerated space, keeping food and other perishables cool.

Heat exchangers in power plants and chemical processing facilities rely heavily on copper alloys. These intricate devices enable the transfer of heat between different fluids. This is done without allowing them to mix. This process is vital for energy efficiency and process control. The ability of copper to quickly absorb and release heat ensures optimal performance and prevents overheating, thereby increasing the overall efficiency and safety of these systems.

Industrial Processes: The Unsung Hero of Thermal Management

Beyond dedicated cooling systems, copper's specific heat plays a crucial, often unseen, role in various industrial processes. Industries that involve high temperatures or require precise temperature control frequently utilize copper components to manage thermal energy effectively.

For example, in metal casting, copper molds can help to rapidly cool molten metal. This allows it to solidify into the desired shape while maintaining dimensional accuracy. Similarly, in welding processes, copper heat sinks can dissipate heat away from the weld zone. This prevents overheating and distortion of the surrounding material.

The utilization of copper in these processes is not accidental. Its specific heat allows for efficient heat absorption. It thereby allows the maintaining of consistent temperatures. It will also prevent thermal damage and maintain product quality.

Electronics: Dissipating the Heat of Innovation

The relentless miniaturization and increasing power density of electronic devices have created a critical need for effective heat dissipation strategies. Copper, with its thermal properties, has emerged as a key player in managing the thermal loads within these devices.

Heat sinks, often made of copper or copper alloys, are attached to heat-generating components like CPUs and GPUs to draw heat away and dissipate it into the surrounding air. This prevents overheating, which can lead to performance degradation or even permanent damage.

Copper is also used in printed circuit boards (PCBs) to conduct heat away from sensitive components. As electronic devices become more powerful and compact, the demand for efficient thermal management solutions will only increase. Copper's specific heat will continue to be essential in ensuring the reliability and longevity of these devices.

Construction: Plumbing and Beyond

While often overlooked, copper's specific heat also contributes to its utility in the construction industry, particularly in plumbing systems. Copper pipes are commonly used for both hot and cold water distribution. Their ability to efficiently conduct heat ensures that hot water stays hot for longer and cold water remains cool.

This thermal property is especially important in energy-efficient buildings, where minimizing heat loss and gain is a priority. Furthermore, copper's resistance to corrosion and its durability make it a reliable and long-lasting material for plumbing applications. Beyond plumbing, copper's thermal mass can also contribute to the overall thermal stability of buildings. It helps to moderate temperature fluctuations and reduce energy consumption for heating and cooling.

Practical Applications: Leveraging Copper's Specific Heat in the Real World The theoretical understanding of copper's specific heat is valuable, but its true worth shines when applied to solving real-world engineering challenges. Copper's ability to absorb and dissipate heat efficiently makes it indispensable in a wide array of applications. Its thermal properties are not merely academic; they are the bedrock of countless technologies and industrial processes that shape our daily lives. Cooling Systems and Heat Exchangers: A Thermal Symphony One of the most prominent applications of copper's specific heat lies in cooling systems and heat exchangers. These systems are designed to transfer heat from one medium to another, and copper's high thermal conductivity and respectable specific heat make it an ideal material for the job. In HVAC (Heating, Ventilation, and Air Conditioning) systems, copper coils are used extensively to absorb or release heat as air passes over them. This allows for efficient temperature regulation in buildings. Similarly, in refrigeration systems, copper tubing facilitates the transfer of heat away from the refrigerated space, keeping food and other perishables cool. Heat exchangers in power plants and chemical processing facilities rely heavily on copper alloys. These intricate devices enable the transfer of heat between different fluids. This is done without allowing them to mix. This process is vital for energy efficiency and process control. The ability of copper to quickly absorb and release heat ensures optimal performance and prevents overheating, thereby increasing the overall efficiency and safety of these systems. Industrial Processes: The Unsung Hero Beyond dedicated cooling systems, copper's specific heat plays a critical, often unseen, role in countless industrial processes. From maintaining optimal reaction temperatures in chemical manufacturing to ensuring the reliable operation of heavy machinery, copper components are frequently employed to manage heat flow. The ability to predict and control temperature changes, informed by the specific heat capacity, allows for precise adjustments that enhance productivity and prevent equipment failure. But heat management and transfer, while critical to understanding how copper operates, relies on looking at mass in grams or kilograms. What if instead, you're trying to determine something based on the amount of copper atoms?

Molar Heat Capacity of Copper: A Deeper Dive

While specific heat capacity focuses on the heat required to raise the temperature of one gram of a substance, molar heat capacity provides a different, yet equally valuable, perspective. It shifts the focus from mass to the number of moles, offering insights into the energy absorption characteristics of individual atoms or molecules within the material.

Understanding Molar Heat Capacity

Molar heat capacity is defined as the amount of heat energy required to raise the temperature of one mole of a substance by one degree Celsius (or one Kelvin). Unlike specific heat capacity, which is expressed in J/g°C or J/kg⋅K, molar heat capacity is typically expressed in J/mol⋅°C or J/mol⋅K. This distinction is crucial because it directly relates the heat capacity to the number of particles present, rather than the mass of the substance.

The significance of molar heat capacity lies in its ability to reveal fundamental properties related to the energy storage mechanisms at the atomic level. By comparing the molar heat capacities of different materials, scientists can gain insights into the ways these materials absorb and store energy. It also offers a more standardized basis for comparison, especially when dealing with chemical reactions or phase transitions.

The Molar Heat Capacity Value of Copper

The molar heat capacity of copper is approximately 24.44 J/mol⋅K (or 24.44 J/mol⋅°C). This value indicates the amount of energy needed to raise the temperature of one mole (approximately 6.022 x 10^23 atoms) of copper by one degree Celsius or Kelvin. This value provides a more direct representation of how energy interacts with the atomic structure of copper. When comparing different materials, molar heat capacity offers a standardized way to understand their thermal behaviors.

It's important to note that like specific heat, the molar heat capacity can also vary slightly with temperature, although the change is generally less pronounced.

Connecting Specific Heat and Molar Heat Capacity: The Mathematical Relationship

The relationship between specific heat (c) and molar heat capacity (Cm) is defined by a simple equation: Cm = c ⋅ M Where:

- Cm is the molar heat capacity (J/mol⋅K)

- c is the specific heat capacity (J/g⋅K)

- M is the molar mass of the substance (g/mol)

For copper, the molar mass (M) is approximately 63.55 g/mol. Using the specific heat of copper (approximately 0.385 J/g⋅K), we can calculate its molar heat capacity: Cm = 0.385 J/g⋅K ⋅ 63.55 g/mol ≈ 24.47 J/mol⋅K This calculation demonstrates the direct correlation between these two properties. It highlights that the molar heat capacity is simply the specific heat scaled by the molar mass.

Understanding both specific heat and molar heat capacity provides a more complete picture of copper's thermal behavior. While specific heat is useful for practical calculations involving mass, molar heat capacity offers deeper insights into the atomic level interactions that govern heat absorption and energy storage. Both concepts are crucial for engineers and scientists working with copper in diverse applications.

Video: Copper Specific Heat: The Ultimate FAQ Guide You Need!

Copper Specific Heat: FAQs

Here are some frequently asked questions to help you better understand copper specific heat.

What exactly is specific heat?

Specific heat is the amount of heat energy required to raise the temperature of one gram of a substance by one degree Celsius (or one Kelvin). Different materials have different specific heat values.

How does copper's specific heat compare to other metals?

Copper has a relatively low specific heat compared to many other common metals. This means it heats up and cools down relatively quickly compared to, for example, aluminum or steel, given the same amount of heat input.

Why is copper specific heat important in practical applications?

Knowing the copper specific heat is crucial for calculating how much energy is needed to heat or cool copper in various applications, like electronics, heat sinks, and plumbing systems. It allows engineers to design efficient and effective systems.

Does the state of copper (solid, liquid, gas) affect its specific heat?

Yes, the specific heat of copper changes depending on its state. The values provided usually refer to solid copper. The specific heat will be different for liquid and gaseous copper due to changes in molecular arrangement and interactions.