What Color is Liquid Oxygen? Properties & Uses

Liquid oxygen, crucial for applications ranging from rocket propellant at NASA to medical respiratory treatments, exhibits unique properties distinct from its gaseous state. Oxygen, a vital element discovered by Joseph Priestley, undergoes a phase transition into a liquid at extremely low temperatures, specifically around -183°C (-297°F). This transformation not only changes its density but also its appearance, raising the fundamental question of what color is liquid oxygen? Understanding this color, a pale blue hue attributable to Rayleigh scattering, provides insight into the quantum mechanics governing light interaction with condensed matter and further study of its characteristic properties and uses.

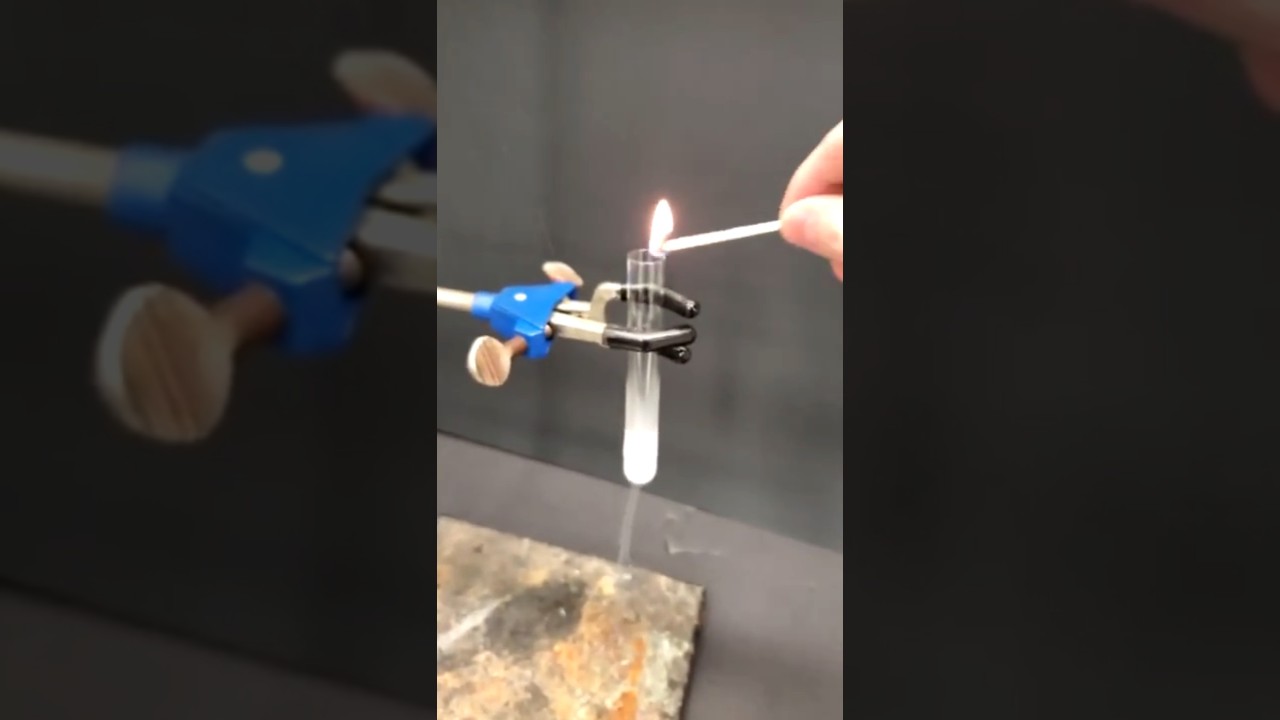

Image taken from the YouTube channel Tommy Technetium , from the video titled Color of liquid oxygen 💚💙 #chemistry #oxygen #chemistryteacher .

Liquid Oxygen (LOx): The Cryogenic Powerhouse Unveiled

Liquid Oxygen, commonly known as LOx, represents a fascinating and crucial form of elemental oxygen. It is created by cooling gaseous oxygen to extremely low temperatures, transforming it into a pale blue liquid. This cryogenic form of oxygen possesses unique properties and plays a vital role across numerous industries.

Defining Liquid Oxygen

At its core, liquid oxygen is simply oxygen (O₂) in a liquid state. What distinguishes it is the cryogenic aspect. Cryogenics deals with the production and behavior of materials at extremely low temperatures. Oxygen's boiling point is approximately -183°C (-297°F). To exist in liquid form, oxygen must be cooled to or below this temperature.

Key Properties and Characteristics

LOx exhibits several key properties that make it invaluable. Firstly, its cryogenic state is critical. Maintaining these low temperatures requires specialized handling and storage techniques.

Secondly, liquid oxygen boasts an exceptionally high oxygen concentration compared to ambient air. This concentrated form makes it a powerful oxidizer, capable of supporting rapid and intense combustion.

Its density is also significantly higher than gaseous oxygen. This allows for a greater amount of oxygen to be stored in a smaller volume, crucial for applications with space or weight constraints.

Significance and Diverse Applications

The significance of liquid oxygen stems from its diverse applications. In the aerospace industry, LOx serves as a critical component of rocket propellant. Providing the necessary oxygen for combustion to power rockets into space.

Industrially, LOx is used to enhance combustion processes in steel production, welding, and other high-temperature applications.

In the medical field, LOx is essential for life support systems. Supplying breathable air to patients with respiratory problems or in environments where breathable air is unavailable or insufficient, such as in submarines or during high-altitude aviation.

The properties and applications of liquid oxygen make it a truly essential material. Its cryogenic nature, high concentration, and versatile usage firmly establish it as a cryogenic powerhouse.

Unveiling the Unique Properties of Liquid Oxygen

Having established the fundamental nature of LOx, we now turn to its defining characteristics. These properties, spanning the physical, optical, and magnetic realms, dictate its behavior and suitability for a multitude of advanced applications. Understanding these properties is crucial for appreciating LOx's utility and safely harnessing its capabilities.

Physical Properties: A Foundation for Functionality

The physical properties of liquid oxygen are paramount to its storage, handling, and applications. Two key attributes stand out: its extremely low boiling point and remarkably high density.

The Chilling Reality of Boiling Point

The boiling point of LOx is approximately -183°C (-297°F). This cryogenic threshold dictates the need for specialized storage and handling procedures.

Maintaining LOx in its liquid state requires continuous insulation and refrigeration to prevent rapid evaporation. Any disruption to these conditions results in the volatile conversion of liquid to gaseous oxygen.

Density: Packing Power in a Small Volume

Liquid oxygen exhibits a significantly higher density than its gaseous counterpart. At its boiling point, LOx has a density of approximately 1.141 g/cm³.

This high density means a greater mass of oxygen can be stored in a smaller volume compared to gaseous oxygen. The increased density is especially important for applications where space and weight are critical considerations, such as in aerospace.

Optical Properties: The Azure Hue of Cryogenic Oxygen

Perhaps the most visually striking characteristic of LOx is its pale blue color. This color arises from the unique way liquid oxygen interacts with light.

Light Absorption and the Blue Hue

Liquid oxygen selectively absorbs certain wavelengths of visible light. This absorption is due to electronic transitions within the oxygen molecules.

The specific absorption pattern results in the transmission and scattering of blue light, giving LOx its characteristic tint. The intensity of the blue color depends on the path length of light through the liquid; larger volumes appear more intensely blue.

Wavelengths at Play

The absorption of light by LOx is strongest in the red and yellow regions of the visible spectrum. This leaves the blue wavelengths relatively unabsorbed, resulting in their transmission and scattering.

It is the scattering of these blue wavelengths that gives liquid oxygen its distinct color. The phenomenon is similar to why the sky appears blue; although the specifics are different, both involve selective scattering of light.

Magnetic Properties: An Unseen Attraction

Beyond its physical and optical attributes, liquid oxygen also exhibits an intriguing magnetic property: paramagnetism.

Paramagnetism Explained

Paramagnetism is a form of magnetism where a material is weakly attracted to an external magnetic field. LOx's paramagnetic nature stems from the electronic structure of the oxygen molecule.

Each oxygen molecule (O₂) possesses two unpaired electrons, which create a net magnetic dipole moment. These unpaired electrons cause LOx to be attracted to magnetic fields, differentiating it from diamagnetic substances, which are repelled.

Electronic Structure and Magnetic Behavior

The presence of unpaired electrons in the molecular orbital configuration of O₂ is the root cause of its paramagnetism.

This electronic structure makes liquid oxygen a unique and interesting material from both a scientific and application perspective. The strength of the paramagnetic effect is temperature-dependent, decreasing with increasing temperature as thermal energy disrupts the alignment of the magnetic dipoles.

From Air to LOx: Production and Handling Techniques

The journey of liquid oxygen from ambient air to a usable cryogenic fluid is a fascinating exercise in thermodynamics and engineering. The primary method for LOx production is air liquefaction, a process that demands meticulous control and sophisticated equipment. Once produced, the extreme temperature requirements of LOx necessitate specialized storage solutions to prevent rapid vaporization and ensure its availability for various applications.

Air Liquefaction: A Deep Dive into the Process

Air liquefaction is the dominant technique for producing LOx on a commercial scale. This process leverages the principles of thermodynamics to cool and separate air into its constituent components, primarily oxygen and nitrogen.

The process generally involves three key stages: compression, cooling, and separation.

Compression: Setting the Stage for Cooling

The initial step involves compressing atmospheric air. This compression increases the air's temperature, but more importantly, it increases its density and prepares it for efficient cooling.

Industrial-scale air compressors are employed to achieve the necessary pressures, typically ranging from several atmospheres to over a hundred, depending on the specific liquefaction cycle.

Cooling: Approaching Cryogenic Temperatures

After compression, the heated air must be cooled dramatically. This is achieved through a combination of techniques, including heat exchangers and expansion turbines.

Heat exchangers allow the compressed air to transfer its heat to outgoing cold gases, pre-cooling the incoming air stream. Expansion turbines further reduce the temperature by allowing the compressed air to expand rapidly, performing work and consequently cooling itself through the Joule-Thomson effect.

Separation: Isolating the Oxygen

Once the air has been cooled to cryogenic temperatures, it enters a distillation column. This column leverages the different boiling points of oxygen (-183°C) and nitrogen (-196°C) to separate the two gases.

As the liquid air rises through the column, nitrogen, with its lower boiling point, vaporizes first and is drawn off. Liquid oxygen, with its higher boiling point, remains in the liquid phase and is collected at the bottom of the column.

This separation process yields high-purity liquid oxygen, ready for storage and distribution.

Storage: Maintaining the Cryogenic State

The extreme cold of LOx presents unique storage challenges. Maintaining its liquid state requires specialized containers designed to minimize heat transfer from the surrounding environment.

Cryogenic Storage Tanks: Engineering for Insulation

Cryogenic storage tanks are engineered to provide exceptional thermal insulation. These tanks typically feature a double-walled construction with a vacuum between the walls.

This vacuum effectively eliminates heat transfer via conduction and convection. Furthermore, the inner tank is often made of materials with low thermal conductivity, such as stainless steel or aluminum alloys, to further reduce heat influx.

The outer tank is typically constructed of carbon steel. The tanks are also designed to accommodate pressure relief valves to safely vent any vaporized oxygen, preventing pressure build-up.

Vacuum Insulation: The Key to Minimizing Heat Transfer

The vacuum insulation is arguably the most critical design feature of cryogenic storage tanks. By removing the air between the inner and outer walls, heat transfer via conduction and convection is drastically reduced.

To maintain the vacuum over long periods, activated charcoal or other desiccants are often placed within the vacuum space to absorb any residual gases that may leak in.

This meticulous attention to insulation allows LOx to be stored for extended periods with minimal losses due to evaporation, ensuring a reliable supply for its diverse applications.

Liquid Oxygen in Action: Exploring Its Diverse Applications

Liquid oxygen (LOx), with its unique properties, finds application across a surprisingly broad spectrum of industries. Its role extends from powering rockets into space to improving the efficiency of industrial processes and sustaining life in environments where breathable air is scarce. The versatility of LOx stems from its high oxygen concentration and cryogenic state, making it an indispensable component in numerous critical applications.

Rocket Propellant: Fueling Space Exploration

One of the most prominent uses of LOx is as an oxidizer in rocket propulsion systems. In this context, LOx reacts with a fuel, such as liquid hydrogen or kerosene, to produce a high-temperature, high-pressure gas that is expelled through a nozzle to generate thrust.

The efficiency and performance advantages of LOx as an oxidizer are significant. Its high density allows for more oxygen to be stored in a smaller volume, leading to a more compact and lighter rocket design.

Furthermore, the high oxygen concentration ensures a more complete and efficient combustion process, resulting in greater thrust and higher specific impulse – a measure of how efficiently a rocket uses propellant.

LOx's Indispensable Role in Aerospace

The aerospace industry relies heavily on LOx for space exploration and satellite deployment. Without LOx, many ambitious space missions would be impossible. Its use as a rocket propellant allows spacecraft to overcome Earth's gravity and venture into the vast expanse of space.

From the early days of spaceflight to contemporary missions, LOx has consistently served as a critical component in enabling humanity's reach beyond our planet.

The future of space exploration will undoubtedly continue to depend on LOx, particularly as we aim for more distant destinations and more complex missions.

Industrial Applications: Enhancing Combustion

Beyond aerospace, LOx plays a vital role in enhancing combustion processes in various industrial sectors. Its use significantly improves the efficiency and effectiveness of these processes.

By introducing nearly pure oxygen into combustion reactions, the concentration of nitrogen – an inert gas that hinders combustion – is greatly reduced. This leads to higher flame temperatures, faster reaction rates, and more complete combustion.

Steel Production

In steel production, LOx is used in basic oxygen furnaces (BOFs) to oxidize impurities in molten iron, converting it into steel. The high-temperature flame produced by the reaction of oxygen with these impurities accelerates the refining process and improves the quality of the steel.

Waste Incineration

LOx is also employed in waste incineration plants to enhance the combustion of waste materials. The introduction of LOx into the incinerator increases the burning temperature, reducing the volume of waste and minimizing the emission of harmful pollutants.

Life Support: Providing Breathable Air

LOx is indispensable in environments where breathable air is not readily available or sustainable. These applications range from underwater exploration to medical treatments, showcasing its versatility in life support systems.

Submarines and Spacecraft

In submarines, LOx is stored in cryogenic tanks and converted into breathable oxygen to sustain the crew during prolonged underwater missions. Similarly, spacecraft utilize LOx to provide a life-sustaining atmosphere for astronauts during space travel.

These closed-environment applications demand a reliable and efficient source of oxygen, making LOx the optimal solution.

Medical Oxygen Therapy

LOx also plays a critical role in medical oxygen therapy. Patients with respiratory conditions, such as chronic obstructive pulmonary disease (COPD), often require supplemental oxygen to maintain adequate blood oxygen levels.

Portable LOx systems provide a convenient and reliable source of oxygen for these patients, allowing them to maintain an active lifestyle while receiving the necessary medical support.

These systems typically consist of a small cryogenic container and a delivery device, such as a nasal cannula, to administer the oxygen to the patient.

Safety First: Handling Liquid Oxygen Responsibly

Liquid oxygen (LOx), while invaluable across various sectors, presents significant hazards that demand strict adherence to safety protocols. These hazards primarily stem from its cryogenic temperature and its capacity to create oxygen-enriched environments. Understanding and mitigating these risks is paramount to ensuring safe handling and preventing accidents.

Understanding the Hazards of Liquid Oxygen

The two primary hazards associated with LOx handling are cryogenic burns and the creation of oxygen-enriched atmospheres. Each poses unique risks that require specific preventative measures.

Cryogenic Burns: The Danger of Extreme Cold

Direct skin contact with LOx can result in severe cryogenic burns, a type of tissue damage caused by extreme cold. The rapid cooling can freeze skin cells almost instantly, leading to effects similar to those of thermal burns.

The mechanism involves the formation of ice crystals within the cells, disrupting their structure and function. This can lead to blistering, tissue necrosis, and potentially long-term damage.

It's crucial to remember that the insulating properties of clothing can be quickly overwhelmed by the extreme temperature of LOx, making even brief contact dangerous.

Oxygen Enrichment: Fueling the Flames

LOx can create oxygen-enriched environments, where the concentration of oxygen is significantly higher than the normal atmospheric level of approximately 21%.

While oxygen is essential for life, an excess can dramatically increase the flammability of materials. Even materials that are normally difficult to ignite can burn readily and intensely in an oxygen-enriched atmosphere.

This poses a significant fire and explosion hazard, as even small sparks or ignition sources can trigger rapid and uncontrollable combustion. Materials like oil, grease, and even some fabrics can become highly flammable in such conditions.

Adhering to Strict Safety Protocols

To mitigate the hazards associated with LOx, strict adherence to established safety protocols is essential. These protocols encompass understanding the Safety Data Sheet (SDS) and utilizing appropriate personal protective equipment (PPE).

The Safety Data Sheet (SDS): Your Guide to Safe Handling

The Safety Data Sheet (SDS) is a comprehensive document that provides detailed information about the hazards of LOx and the recommended safety precautions.

It is imperative to thoroughly review and understand the SDS before handling LOx. The SDS outlines proper handling procedures, potential health effects, first aid measures, and spill response protocols.

Familiarizing yourself with the SDS ensures that you are well-informed about the risks and equipped to handle LOx safely.

Cryogenic Personal Protective Equipment (PPE): Your First Line of Defense

Appropriate personal protective equipment (PPE) is crucial when handling LOx to minimize the risk of cryogenic burns and other injuries.

Essential PPE includes:

-

Cryogenic gloves: Specifically designed to insulate the hands from extreme cold, preventing frostbite and cryogenic burns.

-

Face shield: Protects the face and eyes from splashes and potential exposure to LOx.

-

Apron: Provides an additional layer of protection for the body, preventing contact with LOx spills.

-

Safety glasses: Should always be worn under a face shield to provide continuous eye protection.

Using the correct PPE is not merely a suggestion, but a critical safety requirement. It provides a vital barrier between you and the potential hazards of LOx.

Video: What Color is Liquid Oxygen? Properties & Uses

FAQs: Liquid Oxygen

What causes liquid oxygen to be a specific color?

Liquid oxygen is pale blue due to its absorption of red light. This absorption is a result of electronic transitions within the oxygen molecules when they are very close together at such low temperatures. Therefore, what color is liquid oxygen is directly tied to this light absorption phenomenon.

Besides color, what are some key properties of liquid oxygen?

Liquid oxygen is extremely cold, with a boiling point of -297°F (-183°C). It's also a powerful oxidizer, meaning it readily supports combustion and can react violently with flammable materials. Its density is higher than gaseous oxygen, making it more compact for storage.

What are the main uses of liquid oxygen?

Liquid oxygen is widely used as an oxidizer in rocket propellants. It's also essential in medical applications for patients with breathing difficulties and in industrial processes like steelmaking and welding, where a high concentration of oxygen is required.

Is liquid oxygen dangerous, and if so, why?

Yes, liquid oxygen is dangerous primarily due to its extremely low temperature and its reactivity. Contact with skin can cause severe frostbite. Also, its strong oxidizing nature means it can ignite flammable materials easily and support very rapid combustion or explosions.

So, next time you hear about liquid oxygen, remember it's not just some clear, invisible gas turned cold! It's actually a pale blue substance with some seriously cool properties and a whole lot of important uses. Who knew what color is liquid oxygen could be so interesting, right?