How to Calculate Percent Recovery: Easy Guide

Percent recovery, a critical metric in analytical chemistry, quantifies the proportion of an analyte successfully retrieved after a chemical process. Laboratories use percent recovery to validate analytical methods and ensure the accuracy of experimental results. Determining how to calculate percent recovery usually involves comparing the measured amount of the analyte to the known or theoretical amount initially present in a sample. The Environmental Protection Agency (EPA) often requires percent recovery data to ensure compliance with environmental regulations, particularly in analyzing water and soil samples.

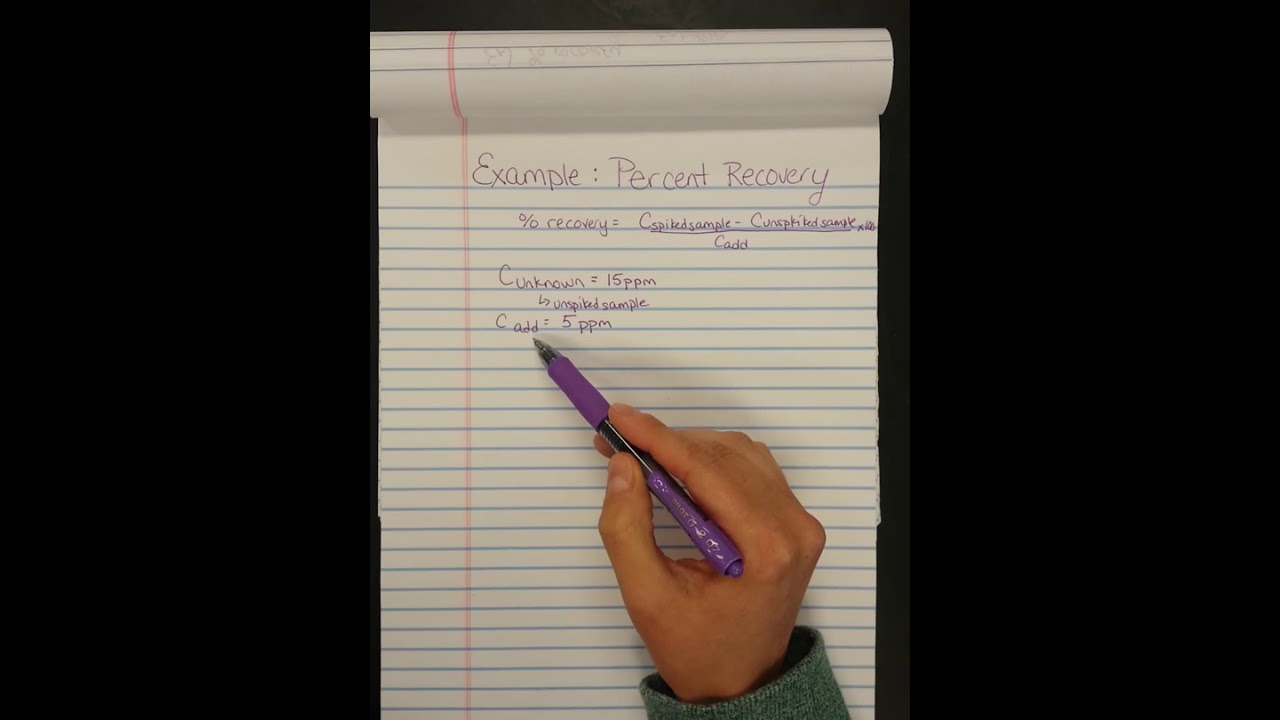

Image taken from the YouTube channel Kathryn Zimmermann , from the video titled Percent recovery calculation .

Understanding Percent Recovery in Chemical Analysis

In the realm of analytical chemistry, achieving accurate and reliable results is paramount. Percent recovery emerges as a critical metric in this pursuit, serving as a key indicator of the validity and reliability of analytical measurements. This section provides an introduction to the concept of percent recovery, underscoring its significance in ensuring data integrity.

Defining Percent Recovery

Percent recovery is defined as the proportion of an analyte that is successfully recovered during an analytical process. It's expressed as a percentage. It reflects the efficiency of the method in extracting, isolating, and measuring the target compound from a sample. A percent recovery of 100% would indicate that all of the analyte was recovered. In contrast, a value less than 100% signals a loss of analyte during the procedure.

In essence, percent recovery provides a quantitative assessment of the accuracy and efficiency of an analytical technique.

Significance in Analytical Measurements

The significance of percent recovery lies in its ability to validate analytical methodologies. It assures the accuracy of the quantitative results generated. It is a cornerstone of quality control and quality assurance protocols in numerous industries. This is because it provides a direct measure of how well an analytical method can reliably quantify a target analyte.

A low percent recovery indicates potential issues such as:

- Analyte degradation.

- Incomplete extraction.

- Matrix interferences.

- Calibration errors.

Addressing these issues is crucial to ensure accurate and reliable data.

Why Accurate Percent Recovery is Vital

Accurate percent recovery is not merely desirable; it is essential for reliable results and informed decision-making.

Inaccurate measurements can have far-reaching consequences, impacting product quality, environmental monitoring, and public health. For example, in the pharmaceutical industry, inaccurate quantification of drug compounds can compromise patient safety and treatment efficacy. In environmental science, it can lead to misinterpretation of pollution levels and ineffective remediation strategies.

Ultimately, reliable analytical data, underpinned by accurate percent recovery, forms the basis for sound scientific conclusions, regulatory compliance, and informed decision-making across various fields.

Theoretical Foundations: The Chemistry Behind Recovery

Before delving into the practical aspects of calculating percent recovery, a firm grasp of the underlying theoretical foundations is essential. This section will elucidate the key chemical concepts and terminology that form the basis of recovery calculations, clarifying the relationship between theoretical expectations and experimental results.

Defining Yield: Theoretical vs. Actual

The term "yield" is central to understanding percent recovery. It represents the quantity of product obtained in a chemical reaction. However, there are critical distinctions between theoretical yield and actual yield that must be understood.

Theoretical yield is the maximum amount of product that could be formed from a given amount of reactant, assuming a perfect reaction with no losses. It is calculated based on the stoichiometry of the balanced chemical equation.

Actual yield, on the other hand, is the amount of product that is actually obtained from a chemical reaction. It is determined experimentally and is almost always less than the theoretical yield due to various factors.

These factors include incomplete reactions, side reactions, and losses during product isolation and purification.

The Percent Recovery Formula

Percent recovery provides a quantitative measure of the efficiency of a process. The formula is expressed as:

Percent Recovery = (Actual Yield / Theoretical Yield) 100%

**

Let's break down each component of this equation:

- Actual Yield: The experimentally determined amount of the target analyte recovered from the sample.

- Theoretical Yield: The expected amount of the target analyte, based on the initial amount and the stoichiometry of the process.

- 100%: This factor converts the ratio into a percentage.

The resulting percentage indicates the proportion of the analyte that was successfully recovered. A value approaching 100% signifies high efficiency, while lower values suggest significant losses during the procedure.

Stoichiometry: The Foundation of Theoretical Yield

**Stoichiometry

**is the branch of chemistry that deals with the quantitative relationships between reactants and products in chemical reactions. It is the cornerstone for calculating theoretical yield.

By using the balanced chemical equation for a reaction, one can determine the molar ratios between reactants and products. This allows the calculation of how much product can be formed from a specific amount of reactant, assuming the reaction proceeds to completion.

For example, consider the synthesis of a drug compound. Stoichiometric calculations are crucial for determining the theoretical yield based on the starting materials and reaction pathway.

Mass Balance and Conservation of Mass

The principle of**mass balance*, also known as the law of conservation of mass, is a fundamental concept in chemistry. It states that mass is neither created nor destroyed in ordinary chemical reactions.

In the context of percent recovery, mass balance implies that the total mass of the analyte should remain constant throughout the analytical process. Any observed loss or gain in mass must be accounted for.

For instance, if an analyte is undergoing extraction from a complex matrix, the mass of the analyte in the original sample should equal the sum of the masses in the extracted solution, plus any remaining in the original matrix, assuming no degradation or external contamination.

Deviations from mass balance can indicate errors in the analytical procedure, such as incomplete extraction or loss of analyte during sample handling.

Factors Influencing Percent Recovery: A Comprehensive Overview

Percent recovery, while conceptually straightforward, is subject to a multitude of influences stemming from various stages of the analytical process. Understanding these factors is crucial for obtaining reliable and accurate results. This section will explore the key variables that can affect percent recovery, ranging from sample preparation and analytical methodology to potential sources of error.

Sample Preparation Techniques

The initial steps in any analytical procedure, those involved in sample preparation, are frequently the most critical in determining overall recovery. Inadequate or inappropriate preparation can lead to significant losses or alterations of the analyte, thereby skewing results.

The Significance of Appropriate Sampling Techniques

The accuracy of any analytical measurement hinges on the representativeness of the sample being analyzed. Sampling techniques must be carefully selected to ensure that the sample truly reflects the composition of the bulk material.

For heterogeneous samples, this may involve techniques such as composite sampling or stratified sampling to minimize bias and variability. If the initial sample is not representative, no amount of analytical rigor can compensate for this initial error.

The Impact of Matrix Effects

The sample matrix—everything in the sample other than the analyte of interest—can significantly affect analyte recovery. Matrix components can interfere with the analytical signal, suppress ionization in mass spectrometry, or bind to the analyte, hindering its extraction or detection.

Strategies for mitigating matrix effects include:

- Matrix matching: Preparing calibration standards in a matrix similar to the sample.

- Standard addition: Adding known amounts of the analyte to the sample to compensate for matrix-related signal suppression or enhancement.

- Matrix isolation/removal: Employing techniques like solid-phase extraction (SPE) or liquid-liquid extraction to separate the analyte from interfering matrix components.

Spiking Samples for Recovery Assessment

Spiking involves adding a known amount of the analyte to a sample before processing. By comparing the measured concentration in the spiked sample to the expected concentration (original + spike), the recovery rate can be calculated.

This technique provides valuable information about the efficiency of the analytical method and helps identify potential problems such as:

- Analyte degradation: Decomposition of the analyte during sample preparation or analysis.

- Adsorption losses: Analyte binding to the walls of containers or chromatographic columns.

- Incomplete extraction: Failure to fully extract the analyte from the sample matrix.

Analytical Methodology

The choice of analytical method and its proper execution are also critical determinants of percent recovery. The inherent accuracy and precision of the method, as well as the skill of the analyst, play significant roles.

The Importance of Accurate and Precise Measurement

Accurate and precise measurements are fundamental to quantitative analysis. Laboratory balances and volumetric glassware must be calibrated regularly and used correctly to ensure the reliability of results.

Errors in weighing or volume measurement directly translate into errors in calculated concentrations and, consequently, in percent recovery.

Method Selection Considerations

Different analytical methods have varying levels of sensitivity, selectivity, and suitability for different analytes and matrices.

- Spectrophotometry and Spectrometry: These techniques are useful for quantifying analytes that absorb light or can be converted into light-absorbing compounds. Proper wavelength selection and calibration are essential for accurate results.

- Chromatography (HPLC, GC): Chromatographic techniques separate analytes based on their physical and chemical properties, allowing for their individual quantification. Method development, including column selection, mobile phase optimization, and detector settings, is crucial for achieving adequate separation and sensitivity.

The choice of method should be based on the specific characteristics of the analyte and the complexity of the sample matrix.

Error Sources and Mitigation

Errors, both systematic and random, are inevitable in any analytical measurement. Identifying and minimizing these errors is essential for maximizing percent recovery.

Systematic vs. Random Errors

- Systematic errors are consistent and reproducible errors that affect the accuracy of the results. Examples include calibration errors, reagent impurities, and consistent biases in measurement techniques.

- Random errors are unpredictable fluctuations that affect the precision of the results. These errors arise from uncontrolled variables such as temperature variations, instrument noise, and analyst subjectivity.

The Importance of Error Analysis

Error analysis involves identifying potential sources of error, estimating their magnitude, and implementing strategies to minimize their impact. This may involve:

- Calibration verification: Regularly checking the calibration of instruments using known standards.

- Blank measurements: Analyzing blank samples to identify and correct for background contamination.

- Replicate measurements: Performing multiple measurements on the same sample to assess precision and identify outliers.

- Control charts: Monitoring the performance of the analytical method over time to detect trends and potential problems.

By diligently addressing these factors, analysts can improve the accuracy and reliability of percent recovery measurements, leading to more informed decisions and better overall data quality.

Applications in Various Industries: Real-World Examples

Percent recovery is not merely an academic exercise; it is a cornerstone of reliable measurement and quality assurance across a spectrum of industries. Its application ensures that analytical data is accurate, defensible, and suitable for its intended purpose, whether that involves safeguarding public health, protecting the environment, or ensuring the efficacy of life-saving medications. This section explores the practical significance of percent recovery in several key sectors.

Pharmaceutical Industry: Ensuring Drug Quality and Efficacy

In the pharmaceutical industry, the stakes are exceptionally high. The accuracy of analytical measurements directly impacts patient safety and the effectiveness of drug therapies.

Percent recovery is a critical parameter at every stage, from drug synthesis and purification to the final formulation of drug products.

Drug Synthesis and Purification

During drug synthesis, percent recovery helps to quantify the efficiency of chemical reactions.

It allows chemists to optimize reaction conditions, improve yields, and minimize the formation of unwanted byproducts. A low percent recovery at this stage can indicate inefficiencies in the synthesis pathway, requiring adjustments to reagents, catalysts, or reaction parameters.

In the purification process, techniques such as chromatography or crystallization are used to isolate the desired drug compound from impurities. Percent recovery measurements ensure that the purification process is effective and that minimal amounts of the drug substance are lost during purification.

Formulation and Quality Control

In formulation, percent recovery is essential for accurately determining the concentration of the active pharmaceutical ingredient (API) in the final drug product.

This is critical for ensuring that each dose contains the correct amount of medication.

Quality control (QC) laboratories routinely use percent recovery to validate analytical methods used for drug product testing. By spiking samples with known amounts of the API and measuring the recovery, analysts can assess the accuracy of the analytical method and identify any potential biases or interferences.

This ensures the reliability of the QC data used to release drug products to the market.

Environmental Science: Monitoring and Remediation

Environmental science relies heavily on accurate analytical measurements to assess pollution levels, monitor environmental quality, and evaluate the effectiveness of remediation efforts. Percent recovery plays a vital role in these processes.

Assessing Contaminant Levels

When analyzing environmental samples (water, soil, air), it is essential to accurately measure the concentration of contaminants, such as heavy metals, pesticides, or organic pollutants.

The complexity of environmental matrices often presents challenges for analytical measurements due to matrix effects or interferences.

Percent recovery studies are used to validate analytical methods and ensure that the measured contaminant levels are accurate. By spiking environmental samples with known amounts of the target contaminants, analysts can determine the recovery rate and correct for any losses or interferences.

Evaluating Remediation Effectiveness

Percent recovery is also critical for assessing the effectiveness of environmental remediation techniques.

For example, when evaluating the success of a soil remediation project, it is important to measure the concentration of contaminants before and after treatment. Percent recovery studies ensure that the analytical methods used to measure contaminant levels are accurate and that any observed reductions in contaminant levels are real and not simply due to analytical errors.

Food Science: Ensuring Safety and Quality

In the food industry, percent recovery is a crucial tool for ensuring the safety and quality of food products. It is used to analyze nutrients, additives, and contaminants in food.

Nutrient and Additive Analysis

Accurate measurement of nutrient content is essential for nutritional labeling and ensuring that food products meet regulatory requirements.

Similarly, accurate measurement of food additives is important for controlling their levels and ensuring that they are within acceptable limits.

Percent recovery studies are used to validate the analytical methods used for nutrient and additive analysis. This helps to confirm that the measured nutrient and additive levels are accurate and reliable.

Contaminant Monitoring

Food safety is a paramount concern for consumers and regulatory agencies alike. Percent recovery plays a critical role in monitoring food products for contaminants, such as pesticides, heavy metals, and mycotoxins.

These contaminants can pose serious health risks if present at elevated levels.

By spiking food samples with known amounts of the target contaminants and measuring the recovery, analysts can assess the accuracy of the analytical methods and ensure that the measured contaminant levels are reliable.

This helps to protect consumers from potential health hazards.

Quality Control/Quality Assurance (QC/QA): A Key Performance Indicator

In QC/QA programs across diverse industries, percent recovery serves as a key performance indicator (KPI) for assessing the performance of analytical methods and laboratories.

It provides a quantitative measure of the accuracy and reliability of analytical data, allowing organizations to track trends, identify problems, and implement corrective actions.

Establishing Acceptance Criteria

Percent recovery data is used to establish acceptance criteria for analytical methods and laboratory performance.

These criteria define the acceptable range of recovery values for a given method or analyte.

If the measured recovery falls outside of the acceptance criteria, it indicates a problem with the analytical method or laboratory procedures that needs to be addressed.

Implementing Corrective Actions

When percent recovery falls outside of the acceptance criteria, it triggers a process of investigation and corrective action.

This may involve troubleshooting the analytical method, re-calibrating instruments, re-training analysts, or revising laboratory procedures.

By systematically monitoring percent recovery and implementing corrective actions, organizations can ensure the quality and reliability of their analytical data and maintain compliance with regulatory requirements.

Advanced Concepts: Deep Dive into Recovery Analysis

Having established the fundamental principles and practical applications of percent recovery, it's crucial to delve into advanced concepts that refine our understanding and application of this critical metric. This section focuses on recovery rate determination, quantitative analysis techniques, and detailed error analysis, providing a comprehensive understanding of the nuances involved in achieving reliable analytical results.

Recovery Rate: Definition, Measurement, and Optimization

Recovery rate, at its core, represents the efficiency of an analytical method in extracting or detecting a target analyte from a sample matrix. It's more than just a percentage; it's a reflection of the entire analytical process, from sample preparation to final detection.

Mathematically, recovery rate is often expressed as the ratio of the amount of analyte detected after processing a spiked sample (a sample with a known amount of analyte added) to the amount of analyte that was initially spiked.

Accurate measurement of recovery rate is paramount. This involves preparing multiple spiked samples at varying concentration levels to assess the method's performance across its working range.

Statistical analysis, such as calculating the mean and standard deviation of the recovery rates, provides a robust evaluation of the method's accuracy and precision.

Factors Affecting Recovery Rate

Several factors can significantly influence the recovery rate:

-

Matrix effects: The sample matrix can interfere with the extraction or detection of the analyte, leading to either suppressed or enhanced signals.

-

Analyte properties: The chemical and physical properties of the analyte, such as its solubility, volatility, and reactivity, can affect its behavior during sample preparation and analysis.

-

Sample preparation techniques: Inefficient extraction, incomplete digestion, or losses during cleanup steps can all contribute to reduced recovery.

-

Analytical method parameters: Inappropriate selection of instrument settings, mobile phase composition (in chromatography), or reaction conditions can negatively impact recovery.

Strategies for Optimization

Optimizing recovery rate is a critical step in method development and validation. This involves systematically addressing the factors that can affect recovery.

-

Matrix-matched calibration: Using calibration standards prepared in a matrix similar to the sample can help to compensate for matrix effects.

-

Internal standards: Adding a known amount of a similar compound (the internal standard) to both samples and standards can correct for variations in sample preparation and instrument response.

-

Optimization of extraction and cleanup procedures: Refining extraction techniques, such as solid-phase extraction (SPE) or liquid-liquid extraction (LLE), and optimizing cleanup steps can improve analyte recovery and reduce matrix interferences.

-

Careful selection of analytical conditions: Choosing appropriate instrument settings, mobile phase compositions, and reaction conditions can enhance analyte detection and minimize losses.

Quantitative Analysis: Calibration Curves, LOD, and LOQ

Quantitative analysis aims to accurately determine the amount or concentration of a specific analyte in a sample. Crucial to this are calibration curves, the Limit of Detection (LOD), and the Limit of Quantitation (LOQ).

Calibration Curves: Constructing and Utilizing

A calibration curve is a graphical representation of the relationship between the instrument response (e.g., peak area in chromatography, absorbance in spectrophotometry) and the known concentration of an analyte.

It's constructed by analyzing a series of standards with known concentrations and plotting the instrument response against the corresponding concentrations. The resulting curve is then used to determine the concentration of the analyte in unknown samples by comparing their instrument response to the curve.

Linearity is a crucial aspect of a good calibration curve. The curve should be linear over the range of concentrations being measured. The correlation coefficient (R2) is commonly used to assess the linearity of the calibration curve, with values close to 1 indicating a strong linear relationship.

Limit of Detection (LOD) and Limit of Quantitation (LOQ)

The Limit of Detection (LOD) represents the lowest concentration of an analyte that can be reliably detected but not necessarily quantified. It's the point at which the signal is significantly distinguishable from the background noise.

The Limit of Quantitation (LOQ) represents the lowest concentration of an analyte that can be quantified with acceptable accuracy and precision. It's typically higher than the LOD.

Both LOD and LOQ are critical parameters for assessing the sensitivity and reliability of an analytical method. They determine the lowest concentration range for which the method is valid. Values below the LOD should be reported as "not detected," while values between the LOD and LOQ should be considered estimates and reported with caution.

The formulas below are often used to calculate LOD and LOQ based on either the standard deviation of the blank or the standard deviation of the response and the slope of the calibration curve.

LOD = 3.3

**(σ/S)

LOQ = 10** (σ/S)

Where:

- σ = the standard deviation of the blank or the standard deviation of the response

- S = the slope of the calibration curve

Error Analysis: Types, Sources, Quantification, and Propagation

Error analysis is a systematic process of identifying, quantifying, and minimizing errors in analytical measurements. Understanding the types and sources of errors is crucial for improving the accuracy and reliability of percent recovery determinations.

Types and Sources of Errors

Errors in analytical measurements can be broadly classified into two categories:

-

Systematic errors (determinate errors): These are consistent and repeatable errors that arise from a specific cause, such as faulty equipment, biased analytical procedures, or incorrect calibration. Systematic errors lead to measurements that are consistently higher or lower than the true value.

-

Random errors (indeterminate errors): These are unpredictable and unavoidable errors that arise from random fluctuations in experimental conditions, such as variations in temperature, pressure, or instrument response. Random errors cause measurements to scatter randomly around the true value.

Specific sources of error in percent recovery measurements include:

-

Sampling errors: Non-representative sampling can lead to inaccurate estimates of analyte concentration.

-

Instrumental errors: Calibration errors, baseline drift, and detector noise can all affect the accuracy of instrument readings.

-

Method errors: Incomplete extraction, incomplete reaction, or interferences from other compounds can lead to inaccurate results.

-

Human errors: Mistakes in weighing, pipetting, or data processing can introduce significant errors.

Statistical Methods for Error Quantification and Propagation

Statistical methods play a crucial role in quantifying and propagating errors in analytical measurements. Key statistical tools include:

-

Standard deviation: A measure of the dispersion or spread of data around the mean. It quantifies the random error in a set of measurements.

-

Confidence intervals: A range of values within which the true value is expected to lie with a certain level of confidence. Confidence intervals provide an estimate of the uncertainty associated with a measurement.

-

Error propagation: A technique for estimating the uncertainty in a calculated result based on the uncertainties in the individual measurements used in the calculation. Error propagation allows us to assess how errors in individual steps of the analytical process contribute to the overall uncertainty in the final result.

By applying these advanced concepts, analysts can refine their understanding of percent recovery and enhance the reliability of their analytical data, ultimately leading to more informed decisions and improved outcomes across various applications.

Video: How to Calculate Percent Recovery: Easy Guide

<h2>Frequently Asked Questions About Percent Recovery</h2>

<h3>What's the difference between theoretical yield and actual yield when figuring out percent recovery?</h3>

Theoretical yield is the maximum amount of product you *should* get based on the balanced chemical equation. Actual yield is the amount you *actually* obtain after performing the experiment. How to calculate percent recovery relies on comparing these two: (Actual Yield / Theoretical Yield) * 100%.

<h3>Why is percent recovery important in chemistry?</h3>

Percent recovery tells you how efficient your experiment was. A low percent recovery might indicate loss of product during purification, incomplete reactions, or errors in measurement. Knowing how to calculate percent recovery helps you troubleshoot and improve your experimental techniques.

<h3>What units do I use when calculating percent recovery?</h3>

The units for actual yield and theoretical yield must be the same (e.g., grams, moles, milligrams). As long as the units are consistent, they will cancel out when you calculate percent recovery, resulting in a percentage.

<h3>Is a percent recovery higher than 100% possible? What does it mean?</h3>

Yes, it is possible to get a percent recovery over 100%. This usually indicates contamination of the product with impurities (like water or unreacted starting material), or errors in weighing. Understanding how to calculate percent recovery properly is crucial for accurate assessment and to identify potential sources of error.So there you have it! Calculating percent recovery doesn't have to be a headache. With these simple steps, you'll be calculating percent recovery like a pro in no time. Now go forth and recover those samples!